PRODUCTOS SHOW

Lista de categorías

Contacte con nosotros

Tee reductor E/F

Categoría:

Productos

Accesorios de HDPE

Accesorios de electrofusión

Teléfono

Description

HDPE electrofusion fittings are a type of connecting elements used in PE pipelines. In another way, these parts are called electrofusion, or fittings with embedded electric heating element. Parts are made of low-pressure polyethylene PE 100 by injection molding or extrusion. After the fitting is mechanically processed. By design, these are couplings for connecting and distributing sections of pipes made of polyethylene, equipped with an electric heating element - a high-resistance conductor, a metal spiral or wire.

E/F Reducing Tee

| Size(mm) | D1(mm) | D2(mm) | L1(mm) | L(mm) | SDR11 |

| 32*25 | 44 | 25.2 | 45 | 118 | √ |

| 50*25 | 62 | 25.2 | 42 | 149 | √ |

| 50*32 | 62 | 32.2 | 59 | 149 | √ |

| 50*40 | 62 | 40.2 | 60 | 145 | √ |

| 63*32 | 77 | 32.2 | 59 | 165 | √ |

| 63*40 | 77 | 40.2 | 70 | 165 | √ |

| 63*50 | 77 | 50.3 | 70 | 165 | √ |

| 75*32 | 91 | 32.2 | 58 | 176 | √ |

| 75*40 | 91 | 40.2 | 58 | 176 | √ |

| 75*50 | 90 | 50.3 | 75 | 180 | √ |

| 75*63 | 90 | 63.3 | 70 | 180 | √ |

| 90*50 | 107 | 50.3 | 75 | 200 | √ |

| 90*63 | 107 | 63.3 | 75 | 200 | √ |

| 90*75 | 107 | 75.3 | 80 | 200 | √ |

| 110*50 | 135 | 50.3 | 80 | 205 | √ |

| 110*63 | 135 | 63.3 | 80 | 205 | √ |

| 110*75 | 135 | 75.3 | 80 | 205 | √ |

| 110*90 | 135 | 90.3 | 85 | 205 | √ |

| 125*75 | 148 | 75.5 | 75 | 247 | √ |

| 125*90 | 148 | 90.5 | 75 | 247 | √ |

| 125*110 | 150 | 110.5 | 85 | 250 | √ |

| 140*110 | 165 | 110.5 | 85 | 280 | √ |

| 160*50 | 190 | 50.3 | 80 | 255 | √ |

| 160*63 | 190 | 63.3 | 80 | 255 | √ |

| 160*75 | 190 | 75.3 | 80 | 255 | √ |

| 160*90 | 190 | 90.3 | 105 | 255 | √ |

| 160*110 | 190 | 110.3 | 105 | 255 | √ |

| 160*125 | 237 | 50.3 | 80 | 280 | √ |

| 200*50 | 237 | 50.3 | 80 | 280 | √ |

| 200*63 | 237 | 63.3 | 80 | 280 | √ |

| 200*75 | 237 | 75.3 | 80 | 280 | √ |

| 200*90 | 237 | 90.3 | 80 | 280 | √ |

| 200*110 | 237 | 110.3 | 105 | 280 | √ |

| 200*125 | 237 | 125.5 | 115 | 350 | √ |

| 200*160 | 237 | 160.3 | 120 | 355 | √ |

| 225*110 | 267 | 110.3 | 105 | 335 | √ |

| 225*160 | 267 | 160.3 | 115 | 335 | √ |

| 250*75 | 297 | 75.3 | 80 | 300 | √ |

| 250*90 | 297 | 90.3 | 85 | 300 | √ |

| 250*110 | 297 | 110.3 | 105 | 300 | √ |

| 250*125 | 297 | 125.5 | 115 | 370 | √ |

| 250*160 | 297 | 160.3 | 120 | 370 | √ |

| 250*200 | 297 | 200.3 | 130 | 420 | √ |

| 315*110 | 373 | 110.3 | 110 | 410 | √ |

| 315*125 | 373 | 125.5 | 95 | 410 | √ |

| 315*160 | 373 | 160.3 | 130 | 410 | √ |

| 315*200 | 373 | 200.3 | 130 | 410 | √ |

| 315*250 | 373 | 250.3 | 150 | 410 | √ |

| 355*110 | 422 | 110 | 105 | 460 | √ |

| 355*160 | 422 | 160 | 125 | 460 | √ |

| 355*200 | 422 | 200 | 125 | 460 | √ |

| 355*250 | 422 | 250 | 140 | 460 | √ |

| 355*315 | 422 | 315 | 140 | 460 | √ |

| 400*110 | 473 | 110 | 105 | 490 | √ |

| 400*160 | 473 | 160 | 130 | 490 | √ |

| 400*200 | 473 | 200 | 130 | 490 | √ |

| 400*250 | 473 | 250 | 140 | 490 | √ |

| 400*315 | 473 | 315 | 145 | 615 | √ |

| 500*110 | 590 | 110 | 115 | 545 | √ |

| 500*160 | 590 | 160 | 130 | 545 | √ |

| 500*200 | 590 | 200 | 130 | 545 | √ |

| 500*250 | 590 | 250 | 145 | 545 | √ |

| 500*315 | 590 | 315 | 145 | 730 | √ |

| 500*400 | 590 | 400 | 160 | 730 | √ |

The process of installing pipes using such fittings is simple. The fastening of parts with pipes or among themselves is carried out using an electrofusion welding machine, which supplies voltage to the heating element. First, the pipe is cleaned with a scraper, then it is inserted into the fitting hole, and the electrodes of the welding machine are connected to the terminals located on the connecting part. When switched on, a current of a certain value flows through a metal wire, electrical energy is converted into thermal energy. The inner surface of the HDPE fitting and the outer surface of the pipe expand, soften, and, when cooled, are firmly soldered together, creating a strong, reliable connection.

Features and Benefits

HDPE electrowelded fittings are used for the installation of engineering communications of various profiles - gas pipelines, water pipelines for industrial and household purposes, highways for transporting chemical media that are inert to low-pressure polyethylene. The popularity of connecting parts of this design is due to their physical characteristics.

Designed for connecting pipes of a wide range of diameters - from 50 to 630 mm.

The amplitude of the working pressure that the fittings can withstand is from 6.3 to 16 atmospheres. This feature allows the use of electrofusion fittings in the most important sections of the pipeline.

The operating temperature for the use of fittings is from 0 to 40⁰C, regulated by ISO and CE Certification. In this regard, they can be used to connect sections of pressure pipelines, including for drinking water.

HDPE electrofusion fittings are relevant for creating corner joints, bends in the pipeline, joining pipes of different diameters, mounting bends, for installation sites with reinforcing and shaped parts.

High resistance to hydraulic vibrations - expansion, shock.

Connections using electrofusion fittings withstand the freezing and thawing of transported liquids, despite the fact that ice has an expansion coefficient of 11%. This indicator indicates the high strength and elasticity of the PE-100+ material, as well as the reliability of the connecting elements.

Various types of electrofusion HDPE fittings are presented on the consumer market today. Couplings for connecting straight pipe sections, tees for branching, transitions for joining pipes of different diameters, saddles for cutting into a pipe bends, plugs for pipeline termination points - all types of parts are provided for specific tasks. In areas where HDPE pipes are laid, electrofusion fittings perform better than similar parts of another system, as they have obvious advantages:

ease of assembly of the structure and low time costs;

the affordable cost of connecting elements allows you to use them for any budget;

to work with electrofusion fittings, high qualifications and a wide range of knowledge are not required;

welding machines are inexpensive and perform calculations automatically, which eliminates errors;

convenience - the ability to work with fittings in hard-to-reach places, in confined spaces;

versatility of use - with any type and diameter of HDPE pipes;

high strength and reliability of connections;

long service life - up to 50 years.

If it is planned to lay a HDPE pipeline, the use of electro-welded components to connect communication lines is the most profitable and convenient solution.

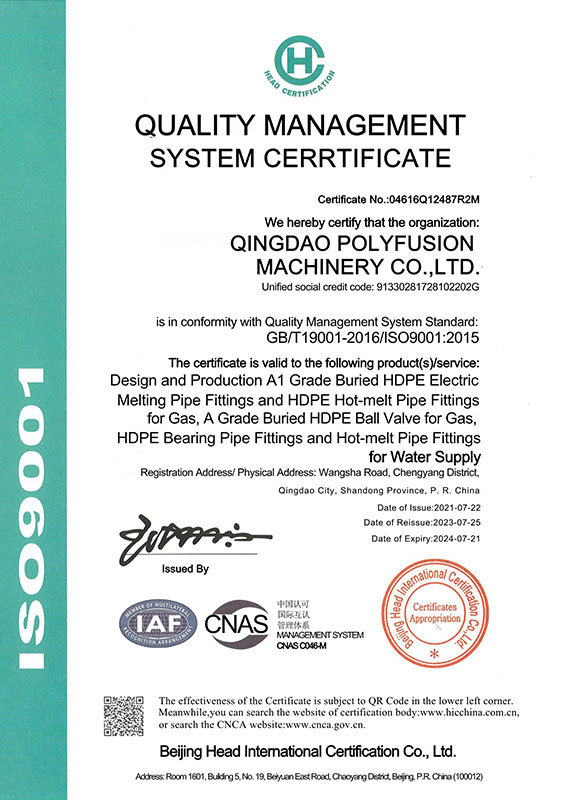

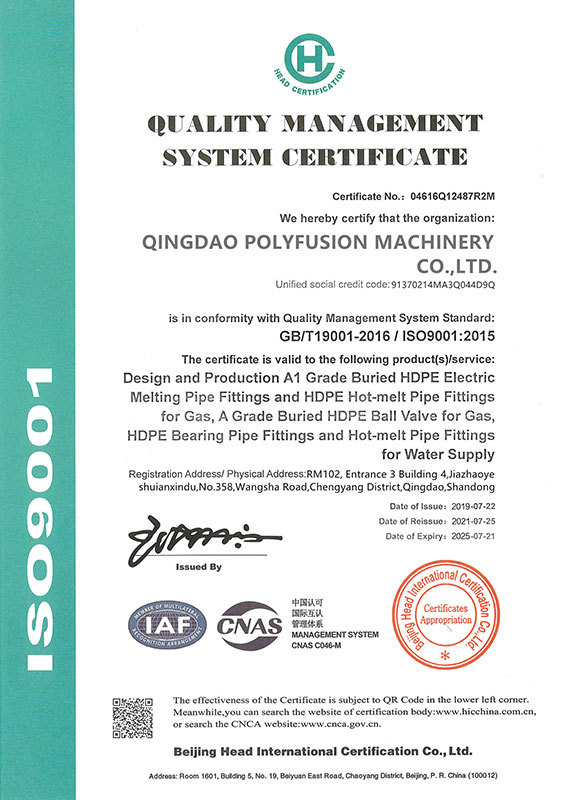

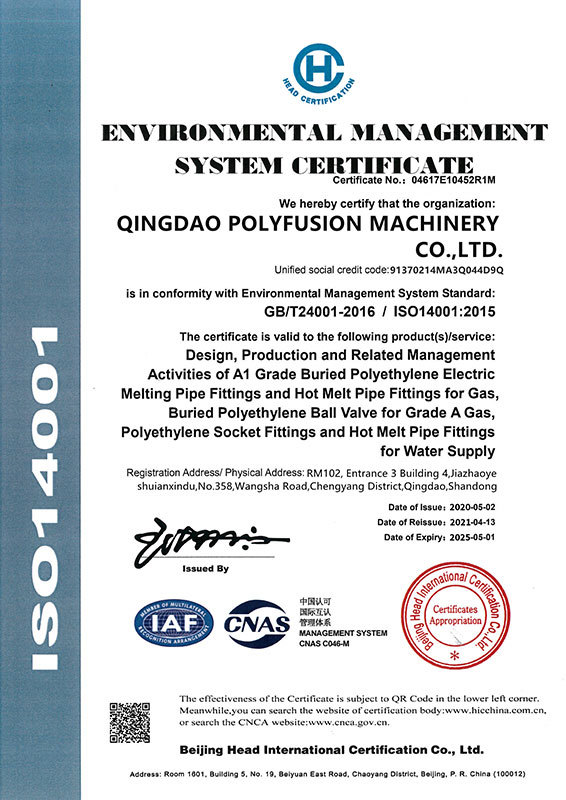

Aseguramiento de calidad

Tenemos el certificado de aprobación ISO9001 y CE,BV,SGS y CNAS con la fuerza del servicio, buena calidad y precio bastante competitivo. El beneficio más grande de los clientes es nuestra meta, calidad de la máquina es la vida de nuestra compañía. Por muchos años de crecimiento, tenemos nuestros mejores socios en el mundo.

Consulta del producto

Polyfusion

Tel: 86-532-6673-3884

Teléfono: 86-15705856568

Buzón: export@qdpolyfusion.com

Адрес: Chengyang промышленная зона, Chengyang, Циндао, Шаньдун, Китай, 266109

Derechos de autor©2023 Polyfusion SEO Licencia comercial